JABRO MK I, II, III & IV

The reason for the page is that both the Zink Petite MK I and MK II utilized JABRO bodies. Ed in the early days like allot of builders used off the shelf parts and the bodies were no exception. It is important to give the JABRO a note in the Zink Petite history as Ed used the bodies of the JABRO MK I for the Zink Petite MK I and the JABRO MK III/IV for the Zink Petite MKII.

JABRO was a name well know in the HMOD world. The name JABRO is made up of the James Brodwell, JA from James and BRO from Brodwell hence JABRO. Jim made four variants of the JABRO cars JABRO I, II, III/IV. The JABRO MK I body was used for the Zink Petite MK I and a JABRO MK III/IV body was utilized for the Zink Petite MK II.

Below is information on the Various JABRO cars plus articles written about the famous breed of little cars.

I feel it is important to give the JABRO cars their due.

JABRO MKI

The car pictured below is a restored JABRO MK I. Ed Zink utilized this body for the Zink MK I car with his own frame and a DKW engine. Below is some articles that have found on the the JABRO MK I.

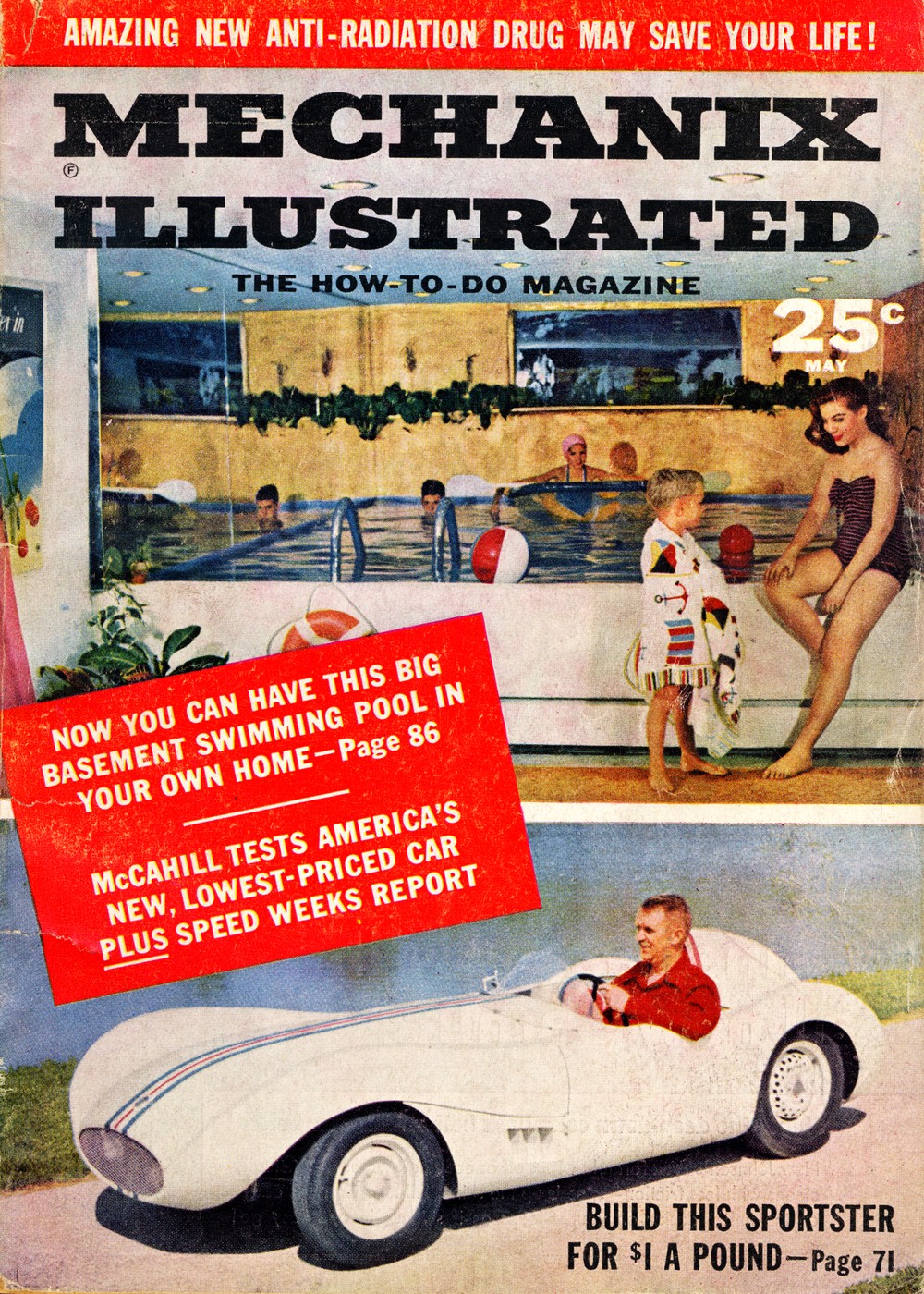

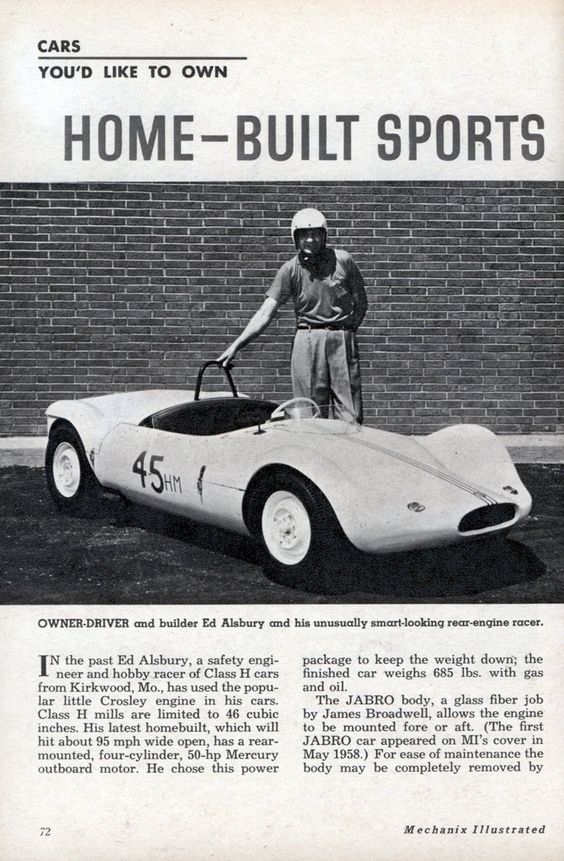

Mechanics Illustrated article on the JABRO MK I

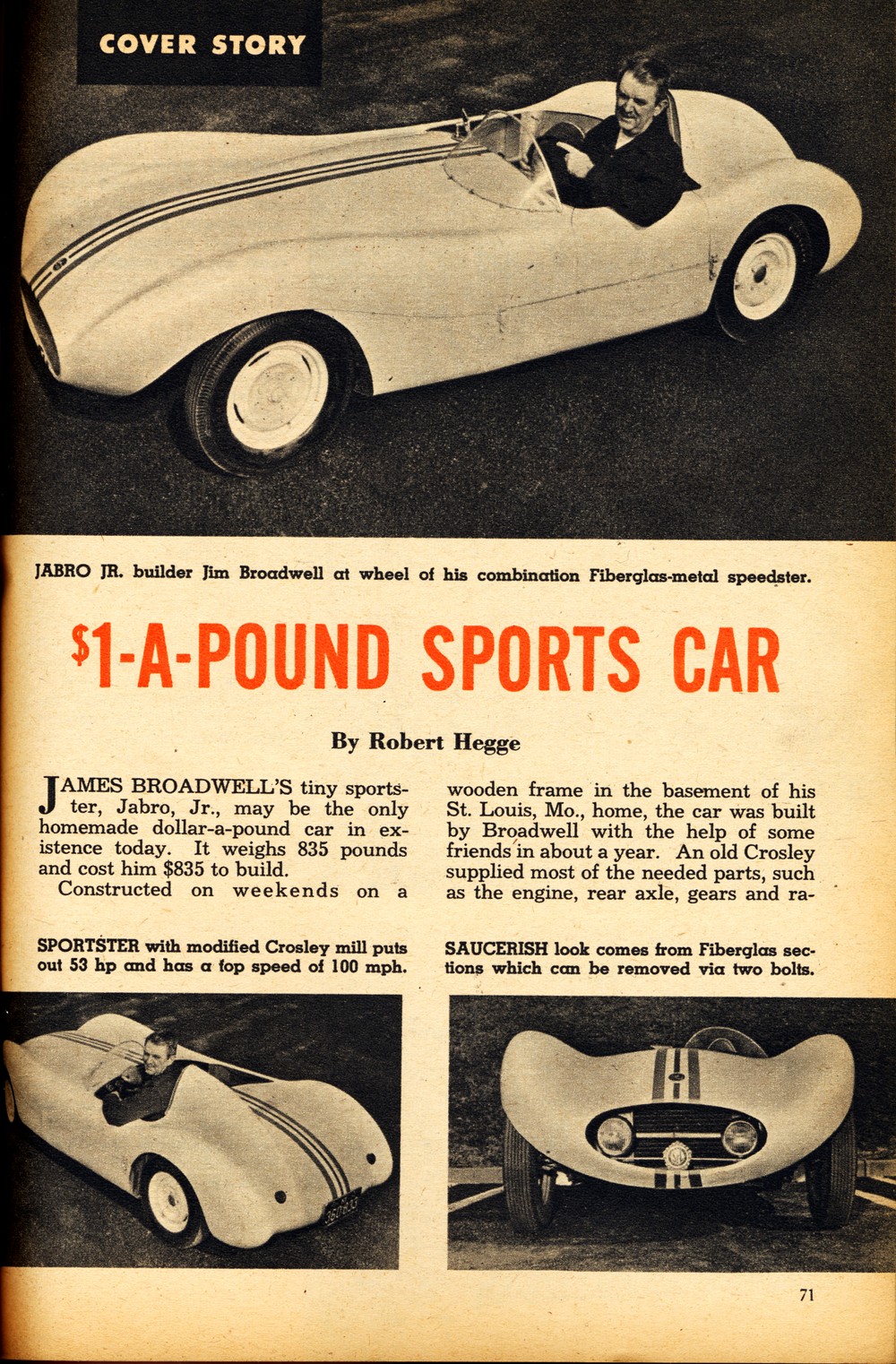

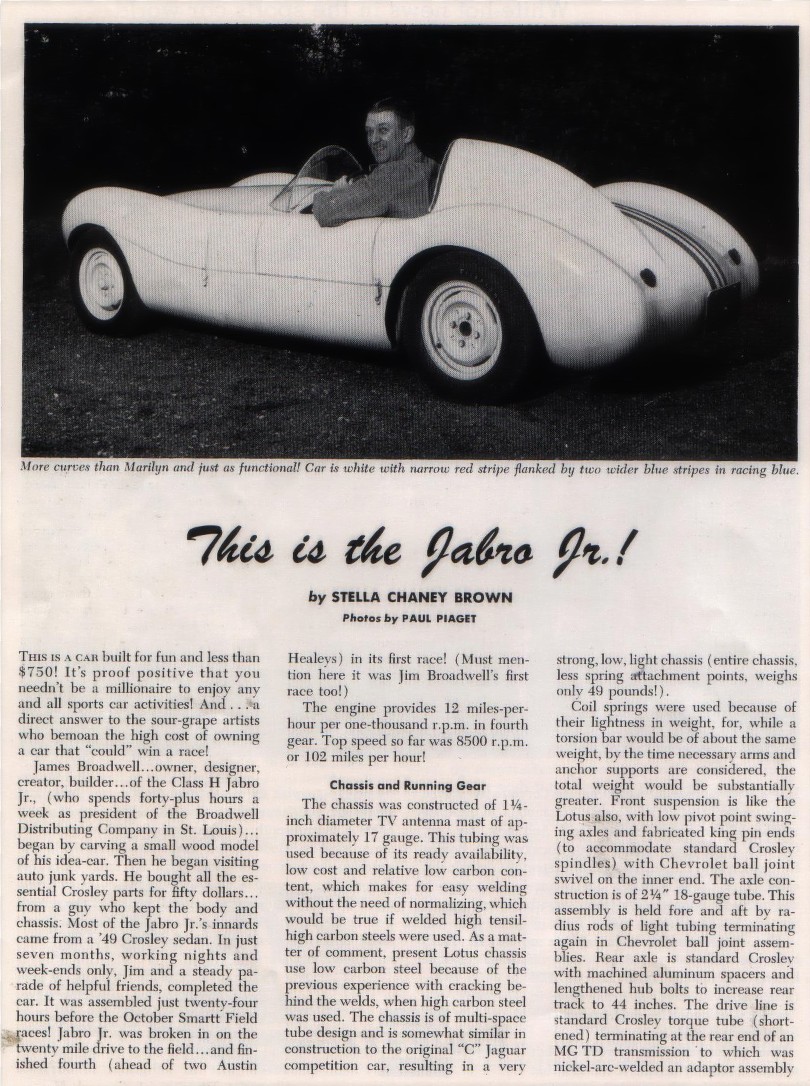

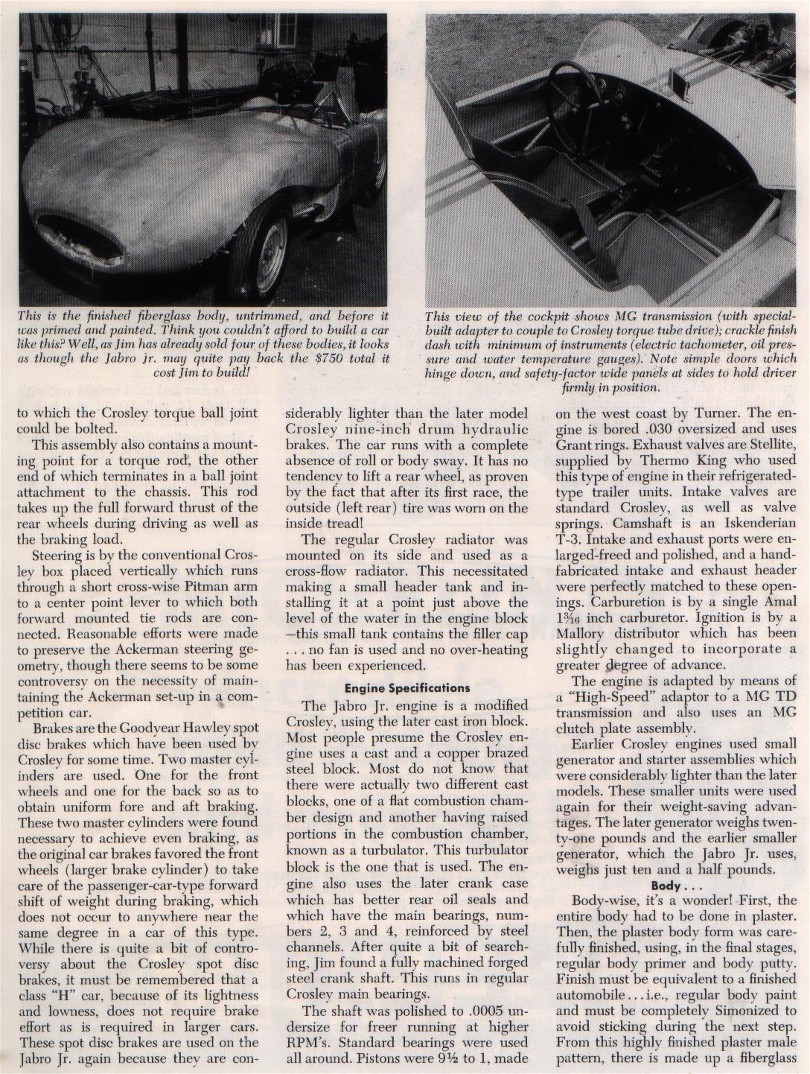

Anybody into Crosleys or H-Modifieds knows the name Jabro. According to Harold Pace and Mark Brinker, writing in Vintage American Road Racing Cars, 1950-1970, St. Louis resident James Broadwell built his first Jabro in the early 1950s using full-size American car parts, but it wasn’t until later in the Fifties that he started to think small. In 1956, Broadwell, president of the Broadwell Distributing Company, bought a 1949 Crosley for its running gear, whittled a wooden model of the final shape he envisioned, then set about building the Jabro Junior, which Robert Hegge wrote about for the May 1958 issue of Mechanix Illustrated.

Pace and Brinker offer a little more detail:

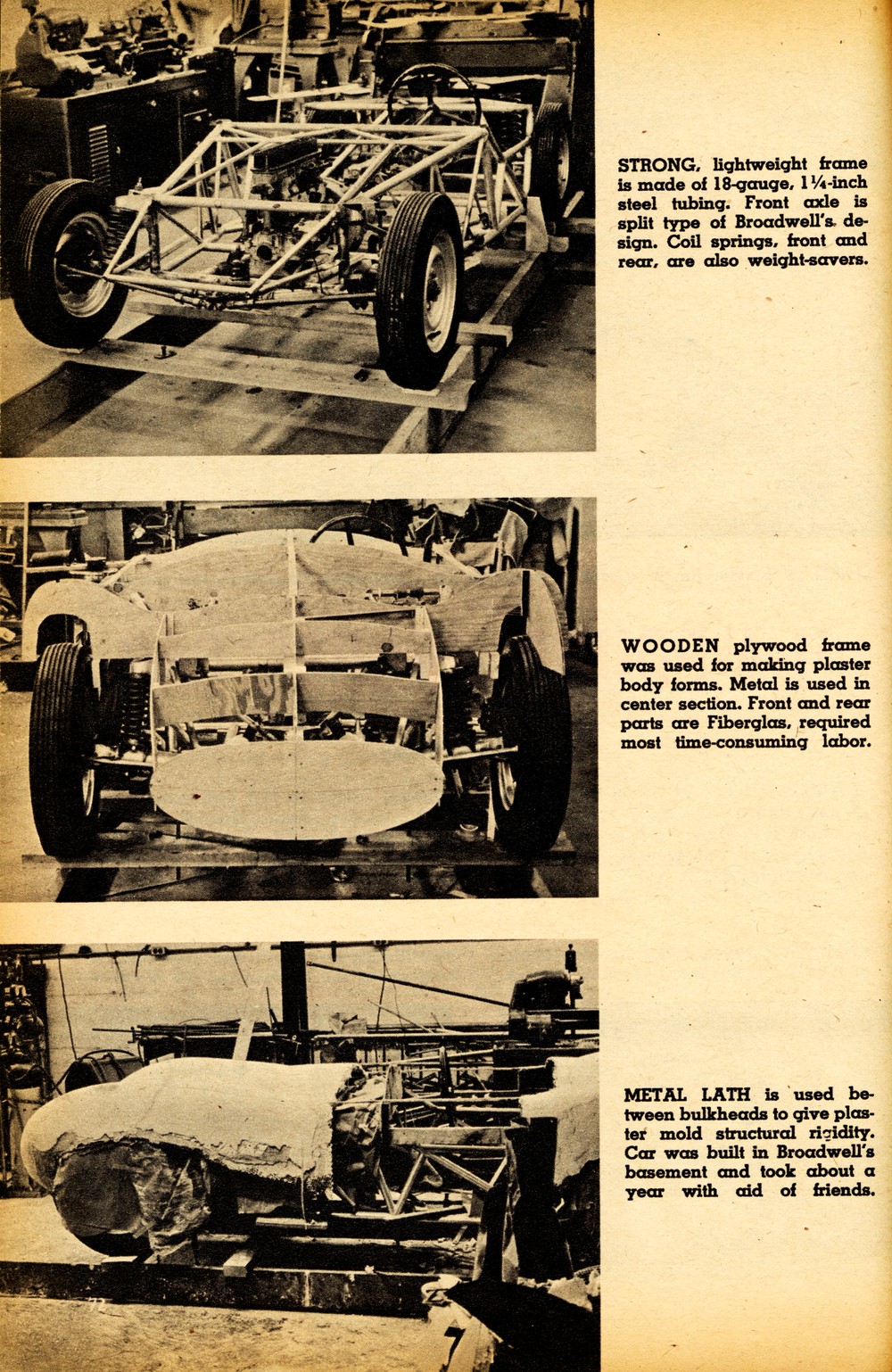

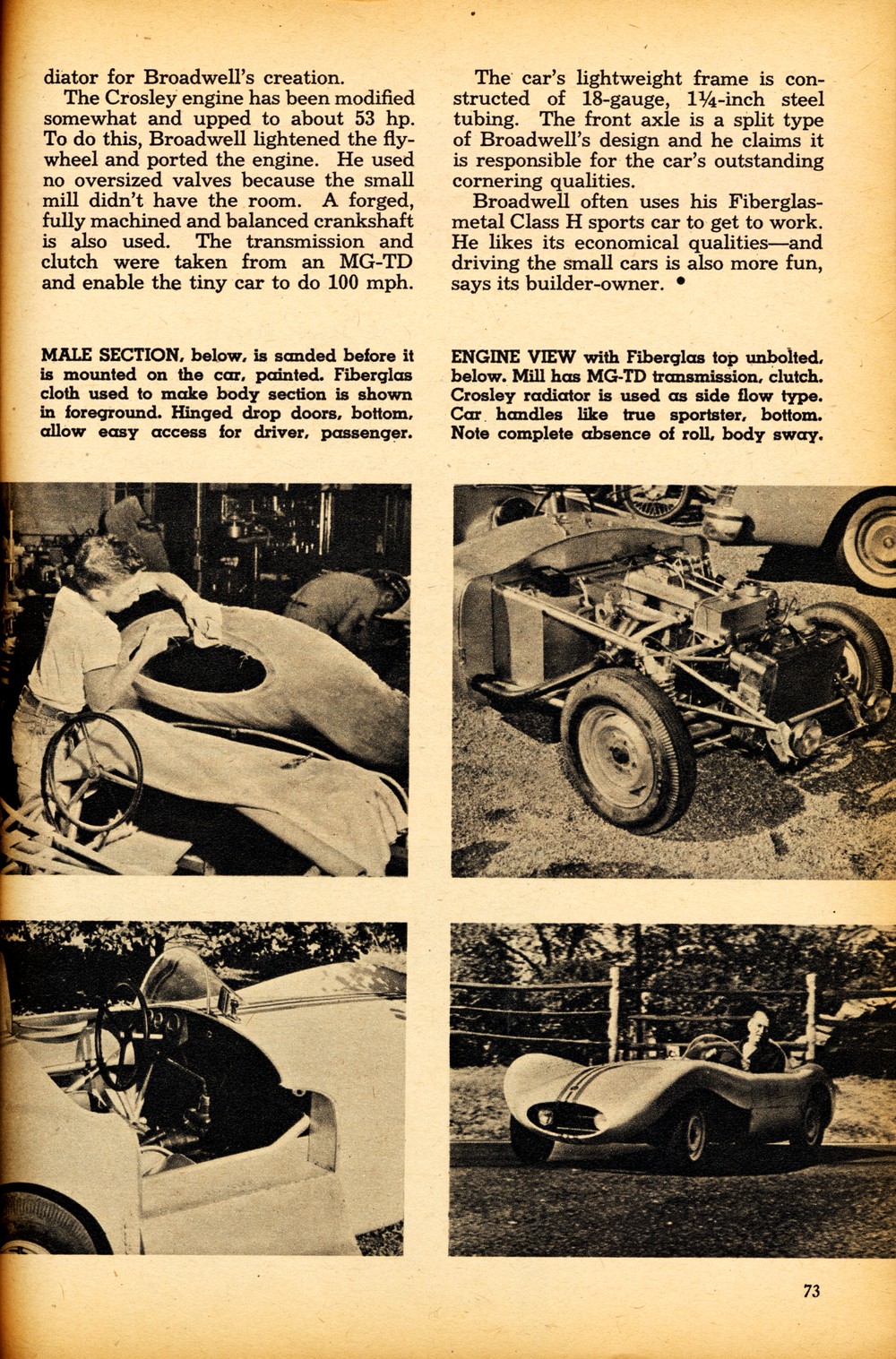

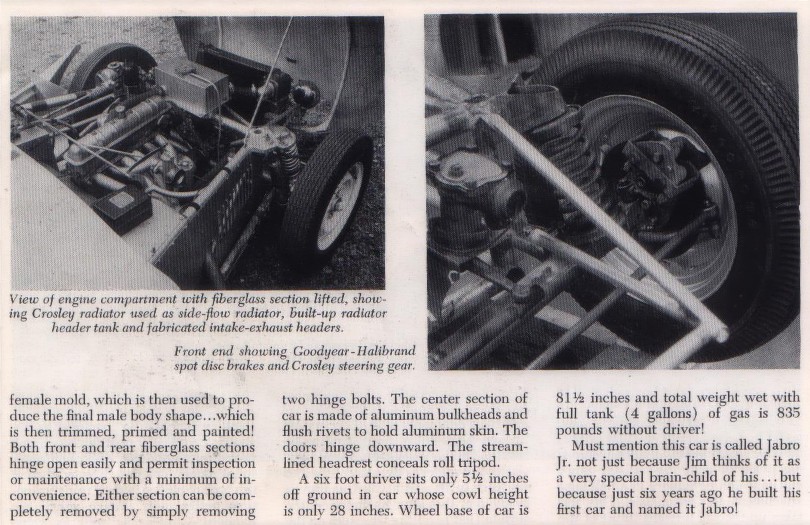

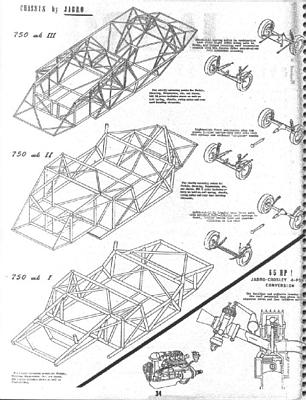

Broadwell’s choice of chassis material was unique in racing history. He welded up 1-1/4-inch TV antenna mast tubing to make a space-frame chassis. This material was chosen due to low cost, availability, and low carbon content (which simplified welding and reduced cracking). the chassis was patterned after the Jaguar C-type and weighed only 49 pounds bare. Coil springs were chosen for their light weight, and low-pivot-point swing axles were used in front, fitted with Crosley spindles mounted to fabricated kingpins with Chevy ball-joint swivels. Tubular radius rods located the axles.

The Crosley disc brakes were activated by dual master cylinders, so brake bias could be adjusted.

Broadwell built up a hot Crosley engine, based on a “Turbulator” cast-iron block. A forged crank and Stellite exhaust valves (sourced from Thermo King, the company that used modified Crosley engines as power units for its refrigerated trucks) were used. An Iskenderian T-3 cam was good for 8,500 RPM, and the head was carefully ported and polished. A single Amal motorcycle carburetor fed the juice to spark, provided by a Mallory distributor.

They note that the Jabro Junior made for a successful race car, winning trophies in 18 of 20 races entered. Over on RacingSportsCars.com, however, there’s only evidence of Broadwell taking part in six races (at least three of which were in the Junior) from 1956-1958, placing no higher than fourth.

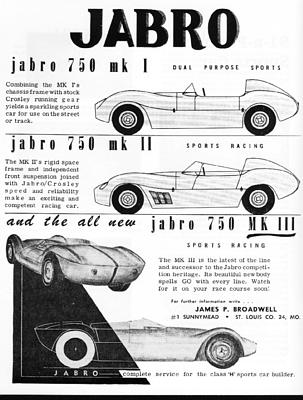

Even if he wasn’t successful on the track, Broadwell was successful in the aftermarket, thanks in part to the above Mechanix Illustrated article. In 1957, he created the Jabro Mk I and the Jabro Mk II, production versions of the Junior that were designed as kits – Broadwell would supply the chassis and body, while the customer would supply the drivetrain and running gear from a Crosley. While the Mk I used a stock Crosley chassis (with solid front axle), the Mk II used swing axles similar to the Junior. A later Mk III used a more advanced design and fewer Crosley parts.

Interestingly, neither Hegge nor Pace and Brinker make direct mention of Ed Alsbury. Writing in the book Road Racing Specials, Barry Heuer noted that Ed and his father, Edgar, wanted to build two Jabros of their own after seeing the Junior. Broadwell then partnered with the Alsburys to put together the production Jabros, welding the frames in the basement of the Alsbury house. Ed Alsbury later went on to develop a mid-engine version of the Jabro.

JABRO MK II

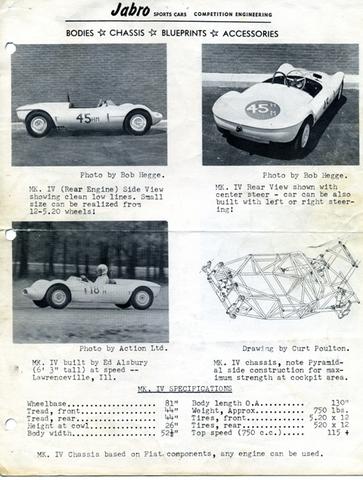

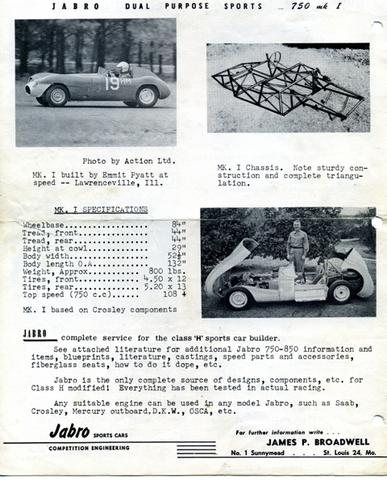

A sales brochure for the JABRO I-III

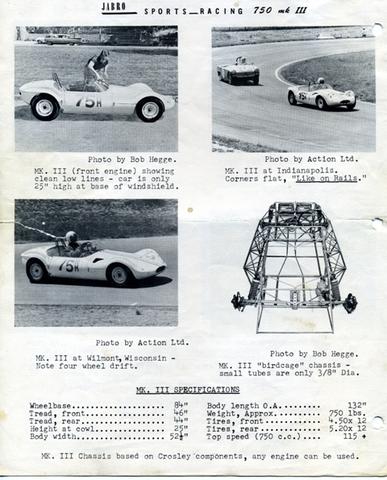

JABRO MK III

With successes on the MK I and II Mr. Broadwell came up with the MK III body which the Zink Petite MKII utilized. The the MKIII car was a front engined car vs the MK IV was a rear engine car. Below are pictures of various MK III cars and MK IV cars.

A JABRO MK III front engine drive with a SAAB 2 stroke engine. There is in the movies tab a video of the car making lovely sounds.

Article from Autoweek and the above JABRO MK III.

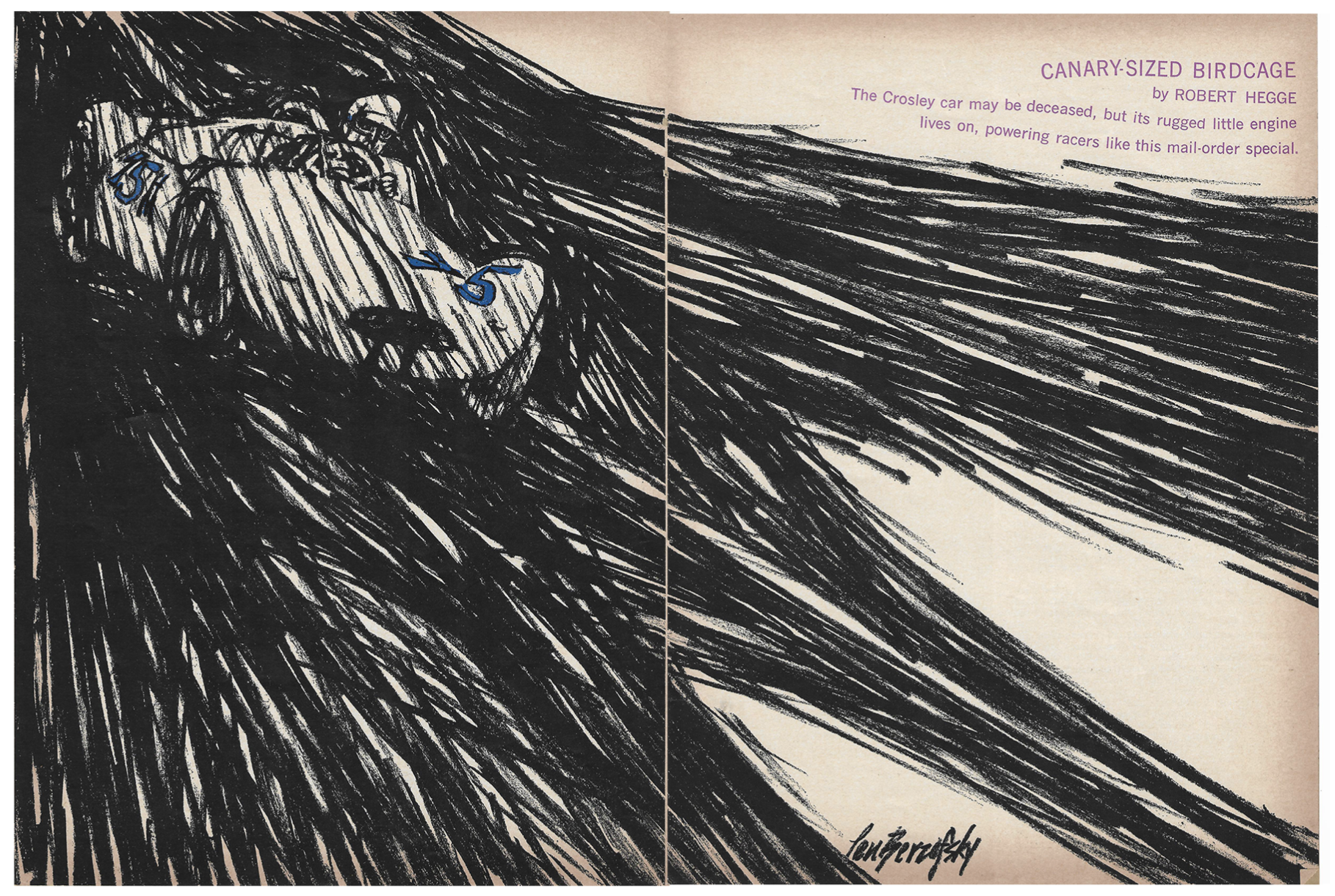

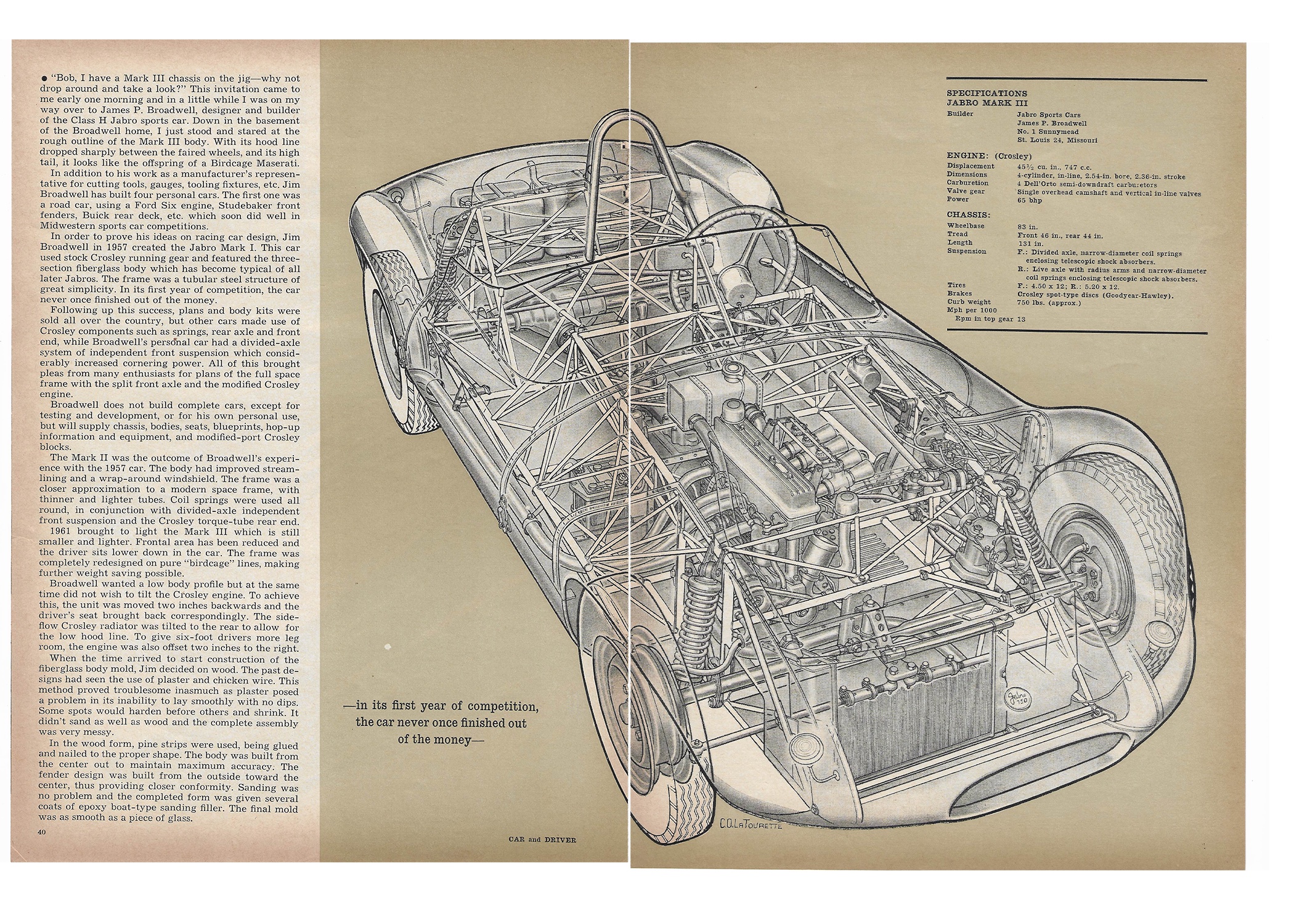

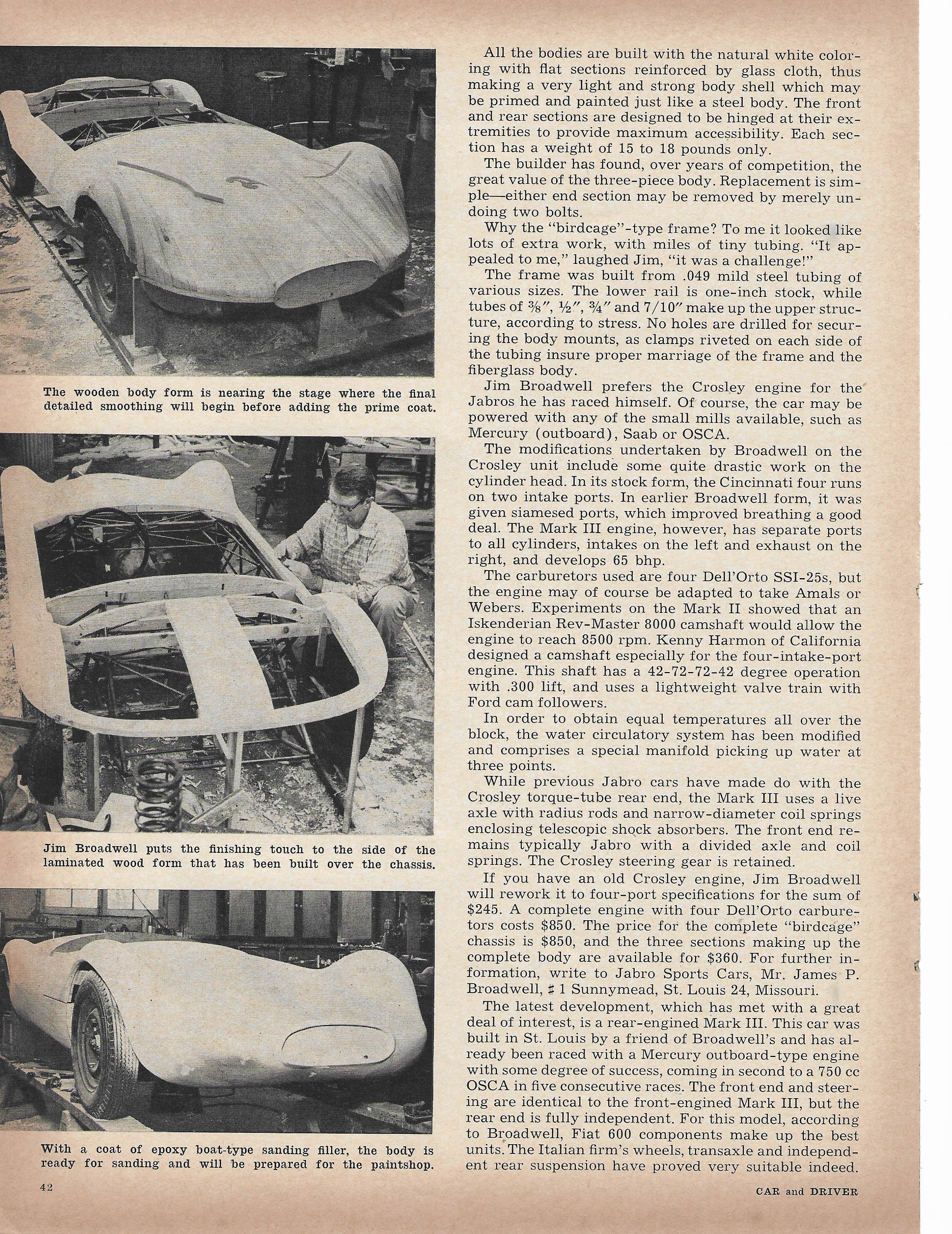

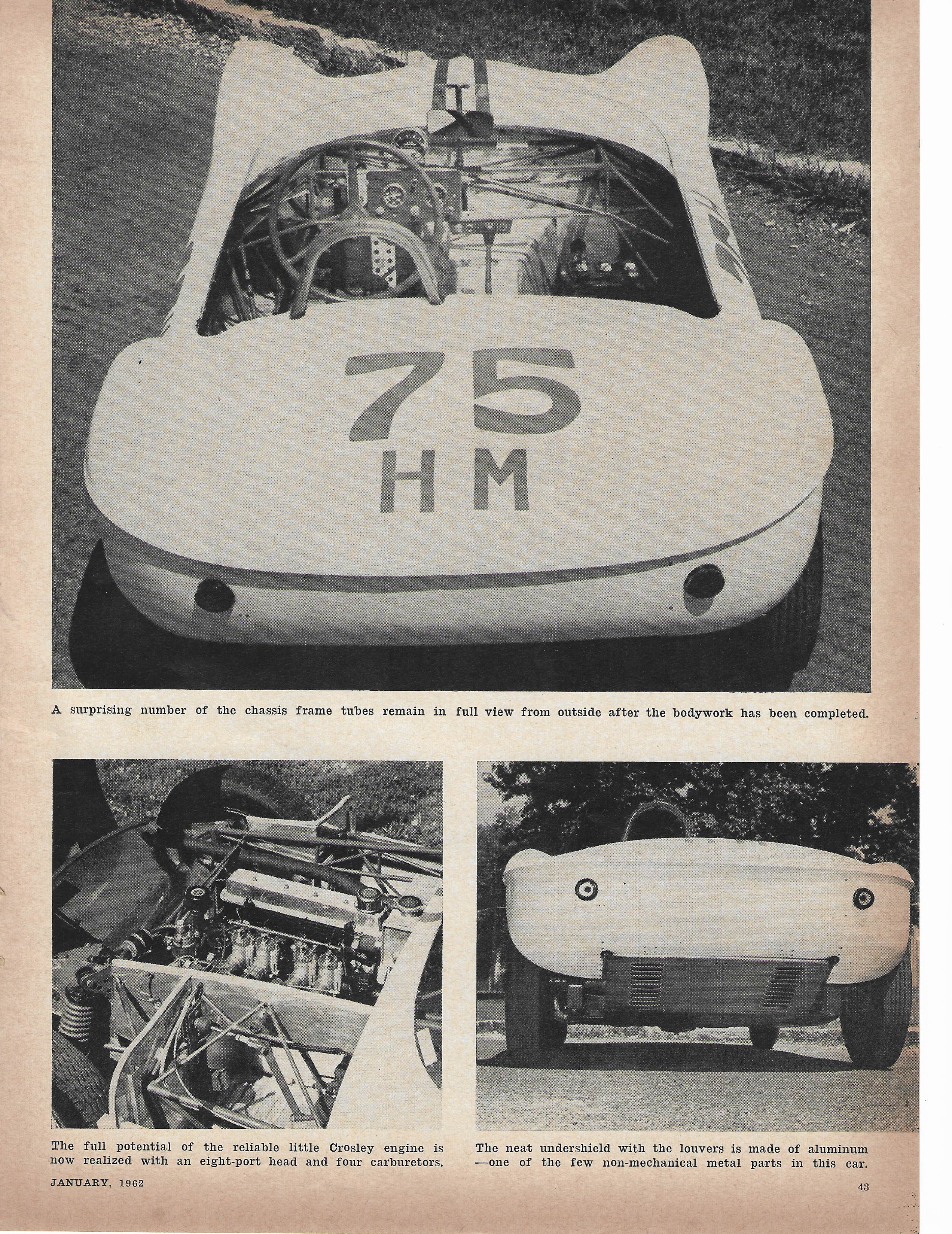

CAR AND DRIVER ARTICLE 1962

JABRO MK IV

The Zink PetiteMK II could be mistaken for a JABRO MK IV but Ed Zink built his own frame and did his own engineering. The cars were quite similar because of the body but beneath is where the real difference was.

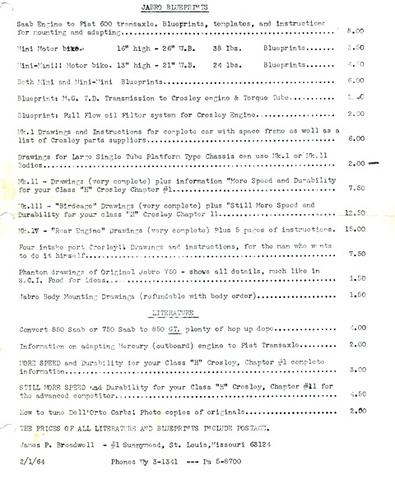

Other sales Brochures

CAR and Driver 1962 pages that were some neat art work

Additional articles

Car & Driver 1962 Car & Driver Jan 1962

Hot Rod Magazine Sept 1962 Hot Rod Magazine Sept 1962

JABRO Guide Jabro Guide

JABRO Sales brochure Jabro Sales flyer

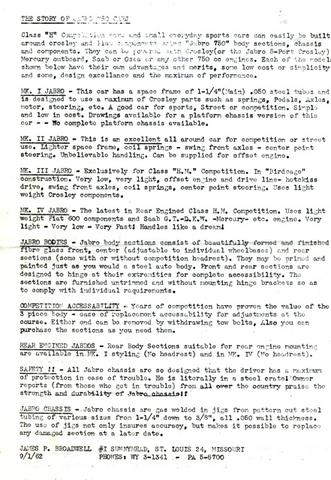

Story of the JABRO Story of the Jabro 750